Nomenclature

This section provides conventions mainly for variable naming, marginally for component naming.

Example of Control Point Naming

By way of introduction, here is an example of how the following rules translate into practical nomenclature for the CHW plant template.

Control Points

Damper and valve models

- take

y1(Boolean) if 2-position, XORy(real, fractional) if modulating

- return

y_actual(real, fractional) for the position feedback (modulating), XORy1_actual(Boolean, open end switch status) andy0_actual(Boolean, closed end switch status)

Fan and pump models

- take

y1for the On/Off command (Boolean, used for constant speed motor starter, and variable speed VFD Run signal), ANDy(optional) for the commanded speed (real fractional or integer, used for variable speed or 2-stage fan motor)

- return

y1_actual(Boolean, status)

(See also command in Glossary.)

Details

Still need to clarify the use of u and y in MBL.

- Is it in reference to the control system (as I/O points) or in reference to the modeled component (either the process—for a sensor—or the controls)?

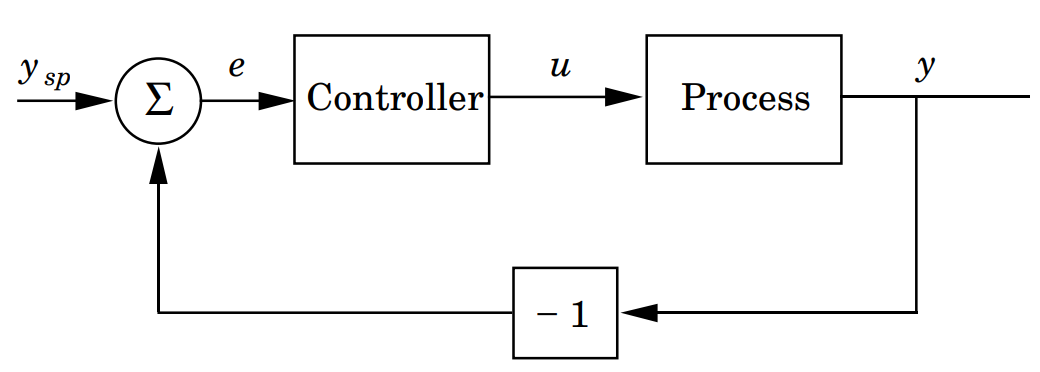

- Is it at all related to control theory as in the diagram below? Obviously not as we would then use

ufor the controller output ande = ysp - yso something in theydomain for the controller input.

Order of Morphemes

In the CamelCase instance name:

The first morpheme indicates what the instance represents.

For example, a controller

ctl, a fanfan, a coilcoiDetails

This is motivated by the naming of

quantity variables: we would not use

SupAirTfor the supply air temperature, but ratherTAirSup,physical connectors: see

port_a.

The suffixes stand for the attributes by order of importance.

For example,

coiCoofor cooling coil,fanSupDrafor a supply fan in a draw-through configuration.For a quantity

the first suffix shall systematically describe the medium (

ChiWat,Air, etc.),the second suffix shall describe the origin of the medium (

ChiWatSup,TAirSup, etc.).Exceptions are only allowed if the quantity is a system characteristic for which there is no ambiguity, e.g.,

dpDamOut_nominalfor the OA damper pressure drop (we don’t mention air) ordpValCoiCoofor the cooling coil control valve (we don’t mention CHW).Similarly (exhaustive list):

TOutorphiOut(air implied)TZon(air implied)pBui_rel(air implied)

All CamelCase morphemes should be used before the first underscore—such as in mAirSup_flow_nominal—with the exception of the physical connectors where we use port_aChiWat.

Do we allow 3-letter capital names such as CHW?

3-letter capital abbreviations are only allowed—and encouraged—in documentation and description strings.

For variable and instance names:

| Rather use | Instead of | To designate |

|---|---|---|

| airHan (*) | AHU | Air handling unit |

| chiWat (*) | CHW | Chilled water |

| conWat (*) | CW | Condenser water |

| coo | CT | Cooling tower or dry cooler |

| eco (*) | WSE | Waterside economizer |

| heaWat (*) | HHW | Heating hot water |

| hex (*) | HX | Heat exchanger |

| hotWat (*) | DHW | Domestic hot water |

| hp | HP | Heat pump |

| hrc | HRC | Heat recovery chiller |

(*) These abbreviations are being used by legacy. If we were to decide today, it would make more sense to rather use lower case abbreviations: chw, cw, hw, dhw, wse, hx, ahu. This is more aligned with the considerations from https://stackoverflow.com/questions/15526107/acronyms-in-camelcase.

Tolerated exceptions (by legacy again, today it would make more sense to use lower case abbreviations):

- COP

- VAV

- PLR

Fixed Position or Non-abbreviated Forms

_nominal,_min,_max,_actual,_defaultalways at the endDetails

minandmaxare attributes of primitive types in Modelica, same asnominal, and should have the same notation, not Min and Max in CamelCase.For design conditions use

_nominalnotDes_flowfor rate per unit of timehave_,is_oruse_for a structural parameter, always at the beginningDetails

Why not

has_? Because “Does it have?”, same for “Does it use?”, but “Is it?”_aand_bfor inlet and outlet ports.

Reserved

Physical Quantities

Pressure:

pis used for absolute pressure,p_relfor relative pressure (duct static, building static, etc.),dpfor a pressure drop across an equipment or a circuit.

Relative humidity: phi

From Buildings.UsersGuide.Conventions:

Mass fraction

- Uppercase

Xdenotes mass fraction per total mass. - Lowercase

xdenotes mass fraction per mass of dry air (absolute humidity).

- Uppercase

TWetBulfor wet bulb

The naming conventions used for variables representing quantities (such as T for temperature) should be used in component names (typically sensors) for the sake of concision.

For example, a sensor for supply air temperature should be named TAirSup instead of senTemAirSup.

Various

We systematically use the parameter cap*_nominal to specify a system capacity. Design engineers are used to provide an unsigned number (positive) for both the heating and cooling capacities. However, MBL users are rather accustomed to using Q*_flow_nominal as a signed parameter. So, for consistency with MBL, each template must make a final assignment of Q*_flow_nominal = +/- abs(cap*_nominal) so that this parameter be always available. Nevertheless, cap*_nominal has no min or max attribute so that the user can provide either a signed or an unsigned variable.

Example

For example, a chiller template would have the following declarations.

mo

mo

Set for a set point, always as the last morpheme: so TZonHeaOccSet not TZonHeaSetOcc.

The letter n is used to represent a number of something (as opposed to num).

The letter y is used to represent a fractional quantity (speed, opening, load) taking as maximum value, e.g., yLoa for PLR.

Prefer

ctltoconfor a controller as the latter is too loose: condenser, configuration, etc.Prefer

cfgtoconfor a configuration.Prefer

lcktolocfor lock-out as the latter is too loose: local, etc.

Legacy Exceptions

Mainly for consistency with MSL we allow the following variable names.

samplePeriod